design

mag |

99

“Speed of construction was a primary consideration

because of the scale of the project and its short time

frame,” Simon Marrion, Probuild’s design manager told The

Builders Choice magazine.“Probuild’s response was to use

precast concrete walls and floor planks for the structural

system.These can be manufactured off-site and erected

quickly.This also defines the external materials, of white

concrete and block work, which are self-finished for ease

of maintenance.”

Russell Perkins, Probuild’s construction manager, echoed

these words and the experience of Rodney Naef.“The use

of precast concrete walls, precast floors and pre-made,

unitised bathroom pods certainly facilitated the actual

construction of the University Hall buildings and ensured

students could occupy them in semester one.”

Austral Precast supplied 611 Austral Deck panels for this

project as well as 143 upstands.

UWA’s University Hall project was awarded the Harold

Krantz Award for Residential Architecture – Multiple

Housing in recognition of the “sensitive and considered”

way HASSELL catered for the varied needs of the student

residents.

Austral Deck is a versatile system that offers a wealth of

design and construction possibilities such as

cantilevering, cast-in balcony and edge formers, and

safety rail fitting points.

It’s versatility doesn’t stop at flooring.Austral Deck can also

be used to construct roofs and lids for tunnels, shafts,

culverts and tanks.Add to that decks and platforms,

including vehicle and pedestrian bridges, curved flyovers,

platforms and jetties.

However it’s as a flooring system that Austral Deck is

unparalleled. Probuild’s Russell Perkins said of his

experience at the University Hall project “The precast and

pre-made elements certainly made a difference.” Or as

Rod Naef said with his usual enthusiasm after that final

pour at Vibe Apartments “It’s a great system, eh!”

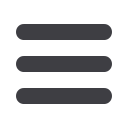

Props are positioned to support the Austral Deck panels

which can span up to 12 metres.The standard width is

2.5 metres.The number of props required is about half

that for a conventional in situ monolithic floor slab.

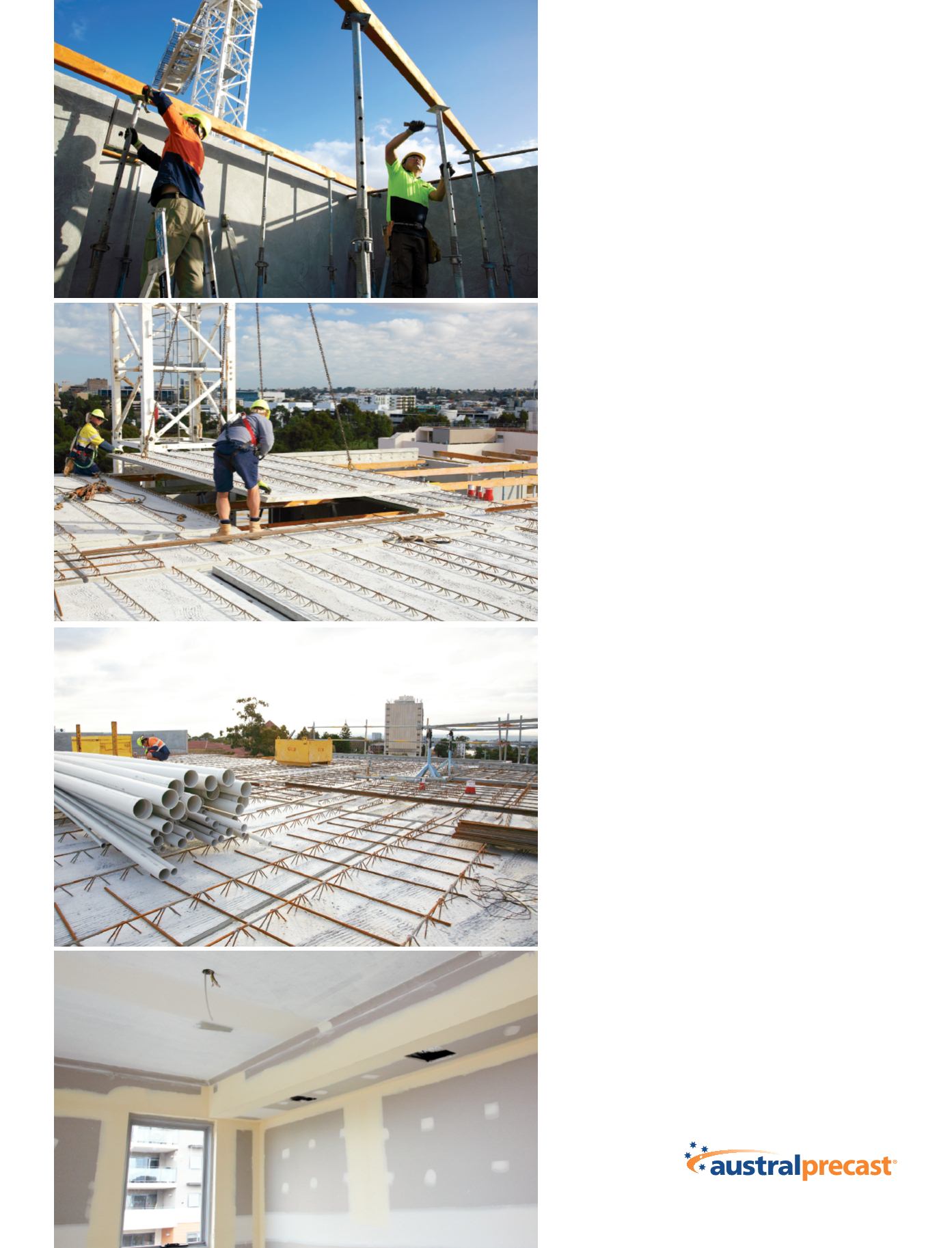

Each Austral Deck panel is lowered into position to create

continuous permanent formwork.The panels are

relatively light and custom made to specification. Panel

thicknesses are 60mm, 75mm and 90mm.

The panels easily support the weight of trades and

materials, enabling services, conduits and ducting to be

installed.The formwork is topped with concrete to form a

monolithic slab.Void formers can be used to reduce the

concrete volume.

All Austral Deck panels are finished to Off-form Class 2,

ready for finishing. Ferrules, conduits, service fixings and

penetrations can be cast in during manufacture.

(Location photography by Gary Peters)