design

mag |

111

The rear of the wall is drained by slotted pipe

in a layer of free-draining aggregate wrapped

in a geotextile material.All blocks are also

filled with aggregate.A layer of geogrid

material is inserted between courses. Finally,

the area behind the walling is back filled with

selected subsoil material and capped with

top soil.

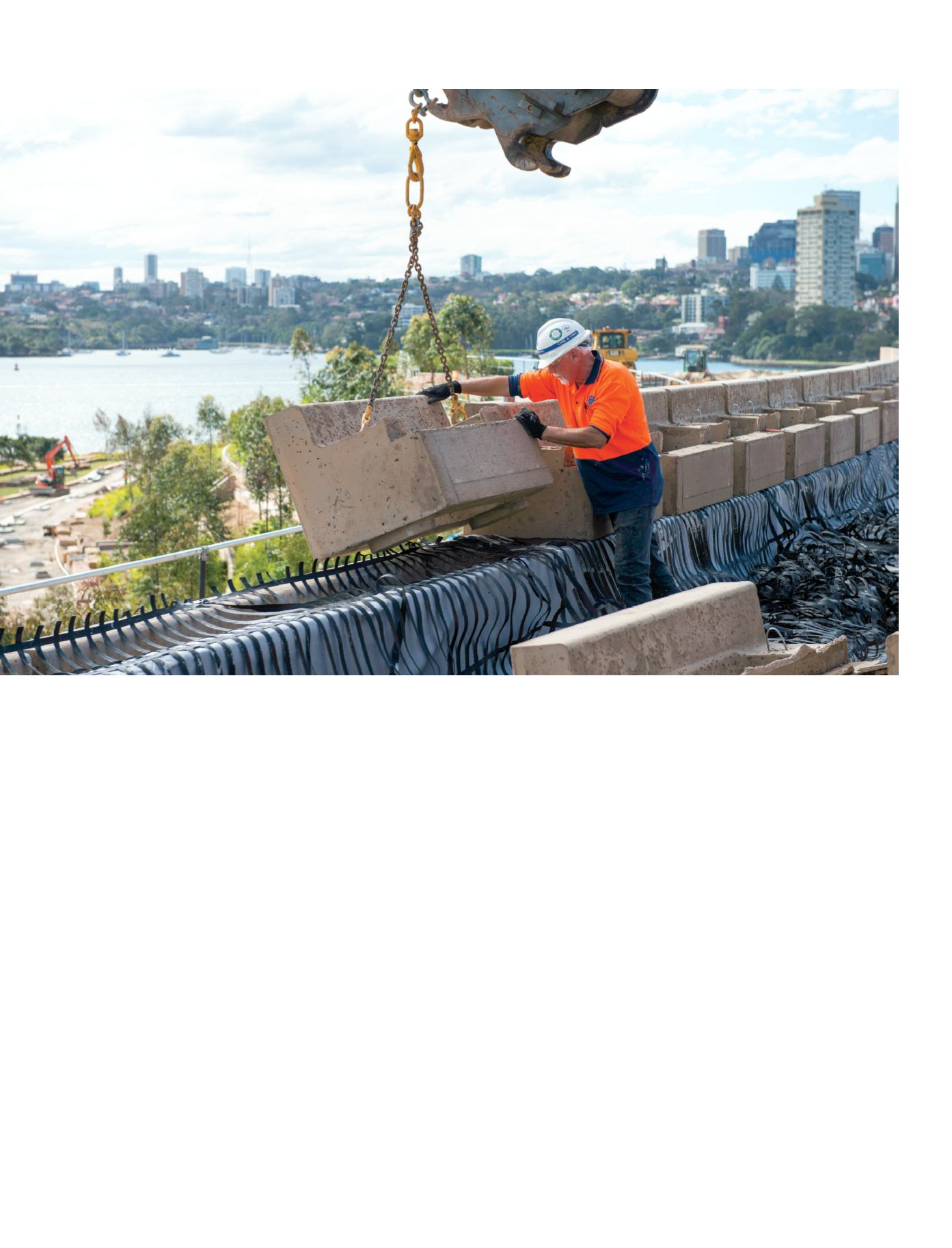

Constructing a Magnumstone retaining wall

is a straightforward process, according to

Daniel De Chellis, Regal Innovations foreman

who led the onsite construction team.

Although the blocks are heavy, his team

members found them easy to lift and

manoeuvre using an excavator boom.Two

chains are attached to lifting points cast into

the units which are then elevated about half

a metre off the ground and transported into

position.

The Magnumstone system offers a range of

advantages over competitive methods. Each

unit is manufactured using nearly half the

amount of concrete required in a traditional

solid concrete retaining wall blocks.

Magnumstone blocks have low absorption

and excellent freeze/thaw characteristics,

ensuring enhanced durability in challenging

environments.

As shown in the Barangaroo project, standard

units can be laid in gentle curves. Special

units are available for tighter curves.

But the greatest advantages are on site.

Blocks can be unloaded two at a time.There

is no mortar to mix, no formwork, no stream of

concrete trucks coming onto the site.

And it’s quick. Daniel De Chellis reports they

are laying up to 130 blocks per day.That’s up

to 80 metres of 1.2 metre high walling per day.

Not bad for just two men and an excavator.

Barangaroo Headland Park is scheduled for

completion in 2015.While the flora settles into

the new landscape, the overall site will evolve

over the following decade into what promises

to be a dynamic and attractive harbourside

precinct.

previous opening.

The new

Magnumstone retaining walls

curve sinuously through

Barangaroo Headland Park, a

six-hectare site fronting Sydney

Harbour.The walls carry

elevated walkways and beds

that are being planted with a

wide range of local flora.

this opening.

The

Magnumstone blocks each

weigh 621 kilograms but are

quickly manoeuvred into

position using an excavator

boom. Lifting lugs are built into

each block.The Magnumstone

block keys into the unit below

and doesn’t require mortaring.